OUR WORK

FOOD INDUSTRY

In the food industry, especially in the confectionery sector, we have established strategic collaborations with our customers to develop specialized components that optimize their production processes. These components include heads for wrapping machines, extrusion nozzles, spare parts for candy die-cutting machines, stick formers, chocolate distribution plates, gum molds, and various tools for new product innovation. By replacing imports, we have managed to optimize costs and significantly reduce response times, thus strengthening market competitiveness.

Candy Dispenser Head Candy Dispenser Head |  Candy Dispenser Head Candy Dispenser Head |  Candy Dispenser Plates Candy Dispenser Plates |

Croquette Extruder Nozzles Croquette Extruder Nozzles |  Sealing Jaws Sealing Jaws |

Marshmallow Extruder Nozzles |

PHARMACEUTICAL

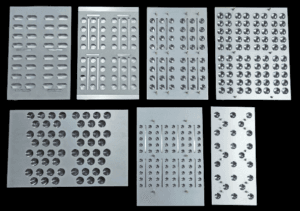

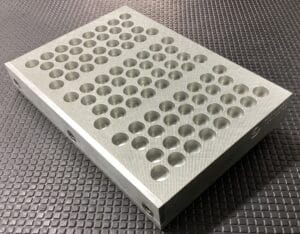

In the pharmaceutical industry, we have collaborated with our customers to develop the capability to design and manufacture complex mechanical components that meet the highest standards of technical quality and asepsis. These include turrets for tablet presses, forming, blow-forming, sealing, and cooling plates, coding systems for blister machines, numerical marking systems, blister cutting dies, tablet press cams, forming punches, and other general spare parts. This approach allows us to meet the demands of our partners in the industry.

Blistering Forming Plate Blistering Forming Plate |  Blistering Tools Blistering Tools |  Blistering Sealing Plate Blistering Sealing Plate |

Blister Cutting Die Blister Cutting Die |  Cyclohexonone Applicators Cyclohexonone Applicators |  Anti-Drip Nozzles Anti-Drip Nozzles |

Blister Forming Roller Blister Forming Roller |  Stainless Steel Mechanical Arm Pipe Cutter Stainless Steel Mechanical Arm Pipe Cutter |  Leva's followers Leva's followers |

CABLES AND CONDUCTORS

To meet the demands of our customers in the cable industry, we have implemented in-house processes for the manufacture of highly customized spare parts, tailored to their unique requirements. We produce extrusion dies and guides, custom markings for meter-by-meter cable labeling, as well as various general components. All of this is carried out while ensuring the use of the highest quality materials and treatments, obtained from our best-in-class partners.

Extruder Dies Extruder Dies |  Markers Marker Markers Marker |  Extruder Die Extruder Die |

Extruder Guide Extruder Guide |  Fiber Optic Connectors Fiber Optic Connectors | Candy Dispenser Head |

MASTERBACH

The manufacturing of components related to the masterbatch production process goes beyond simply replicating original machine parts; it requires in-depth process knowledge to ensure the correct selection of materials and geometries. We produce conveyor segments, kneading segments, drive shafts, and a wide variety of components for different types of extruders.

Mixing Segments Mixing Segments |  Conveyor Segments Conveyor Segments for Extruder Screws |  Splined Axles Splined Axles |

GENERAL MANUFACTURING

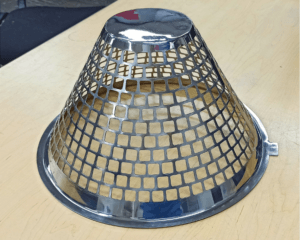

Our processes allow us to serve not only specific market segments but also the industry as a whole, including soap factories, cement plants, food production facilities, and other industries within the national sector.

Conical Filters Conical Filters |  Burin holder Burin holder |  Cutting Scissors Cutting Scissors |

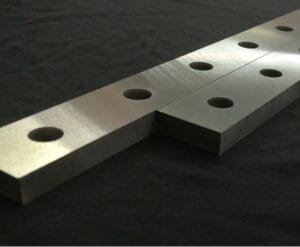

Blades Blades |  Stops in Empack-N Stops in Empack-N |  Test Tube Mold for Soap Test Tube Mold for Soap |

Pneumatic Actuators Pneumatic Actuators |  Cams Cams |  Helical Pinion Gear Helical Pinion Gear |

MOLDS AND DIES

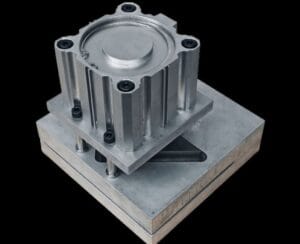

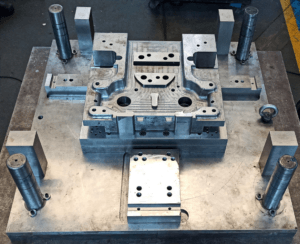

As the core of our company, we have the capacity to design and manufacture all types of molds, including injection molds, blow molds, soap molds, as well as cutting, embossing, and stamping dies. We are prepared to work with any proposed material and geometry.

Triangular Cutting Die Triangular Cutting Die |  Soap Molds Soap Molds |  Cutting Dies Cutting Dies |

Forming Die Forming Die |  Injection Molds Injection Molds |  Blow Molds Blow Molds |

PLASTIC INJECTION

This new line of business has allowed us to innovate in the services we offer. We have the necessary infrastructure to produce any product, not only from conventional materials but also from highly complex engineering plastics, such as nylon, polycarbonate, PET, fiberglass, and neoprene.

Base Legs for Furniture and Beds Base Legs for Furniture and Beds |  Fan Propeller Fan Propeller |  Biosecurity Mask Biosecurity Mask |

OUR CAPABILITIES

CONVENTIONAL MILLING

Milling is a machining process that involves cutting material using a multi-edged rotating tool, capable of moving in virtually any direction along all three axes. The table, on which the workpiece is secured, allows for this versatility, facilitating the creation of complex parts.

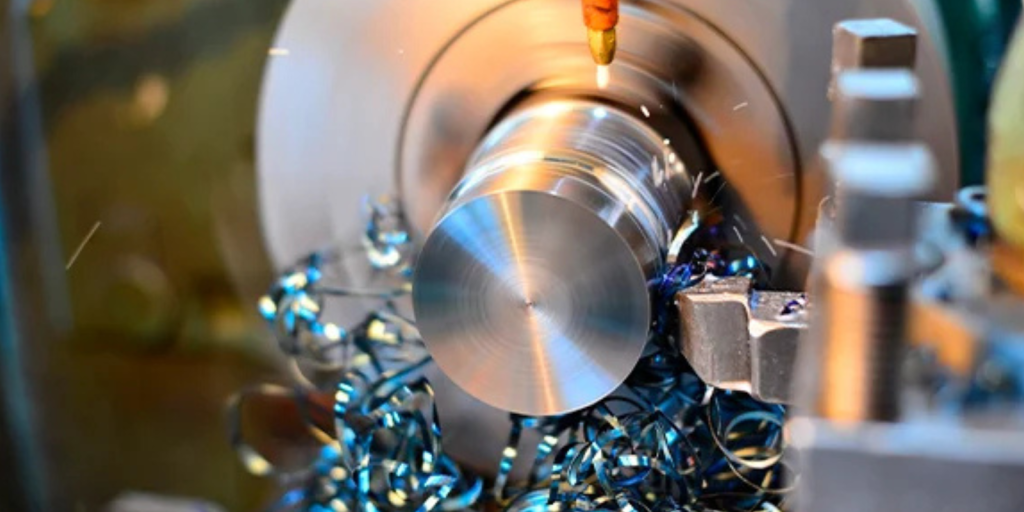

CONVENTIONAL TURNING

Turning is a machining method designed for the manufacture of cylindrical parts. The cutting tool moves linearly while the workpiece rotates. We use high-tech equipment and highly experienced operators, allowing us to produce parts of any complexity.

CONVENTIONAL TURNING

Turning is a machining method designed for the manufacture of cylindrical parts. The cutting tool moves linearly while the workpiece rotates. We use high-tech equipment and highly experienced operators, allowing us to produce parts of any complexity.

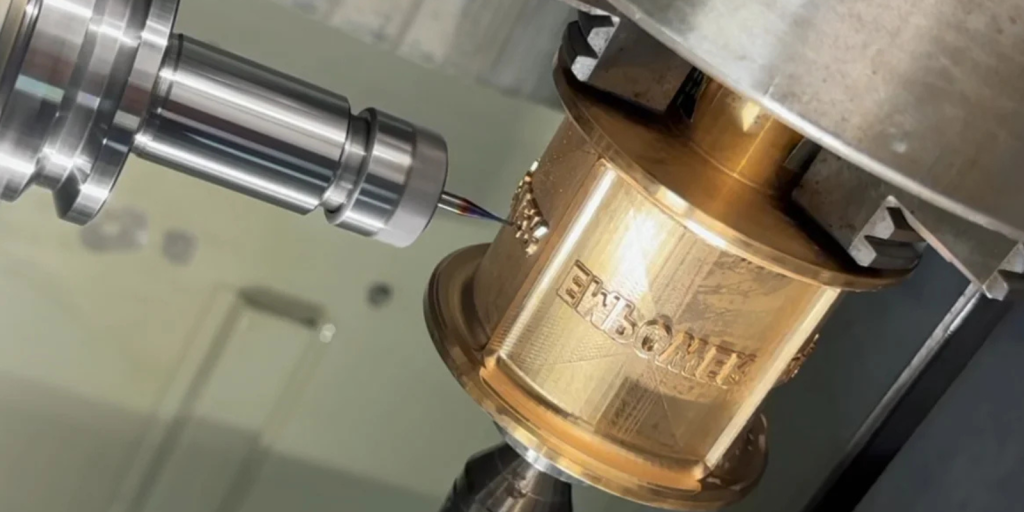

CNC MILLING WITH 4TH AXIS

The Computer Numerical Control (CNC) milling process allows for superior precision and minimized imperfections by automating machining operations. This advanced approach facilitates the creation of complex geometries that are not feasible with traditional manual methods, thus optimizing efficiency and quality in component production.

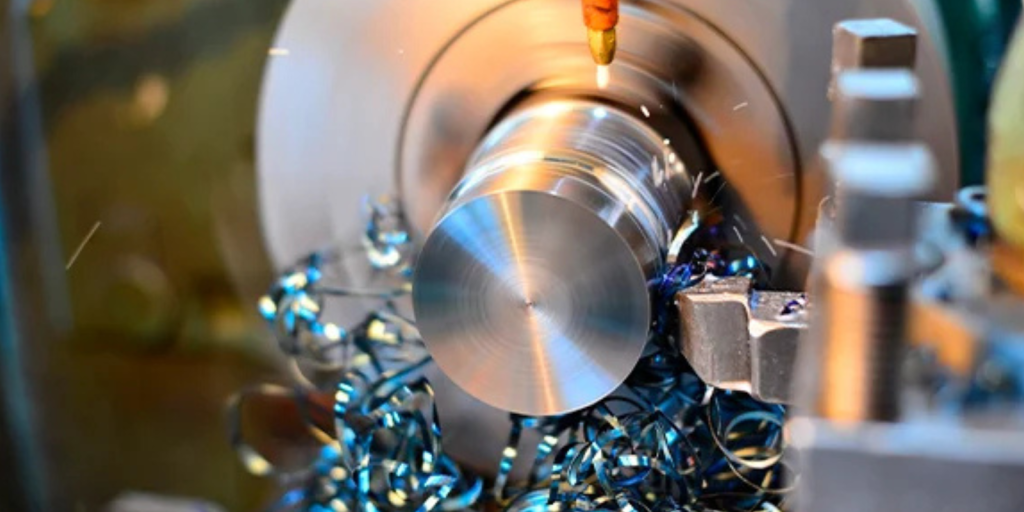

CNC TURNING

CNC turning is a chip-removing manufacturing process based on two fundamental motions: the cutting motion, which is rotary and applied to the workpiece, and the feed motion, which is straight and performed by the tool. This process is characterized by its high precision and efficiency in the machining of complex parts and in mass production.

CNC TURNING

CNC turning is a chip-removing manufacturing process based on two fundamental motions: the cutting motion, which is rotary and applied to the workpiece, and the feed motion, which is straight and performed by the tool. This process is characterized by its high precision and efficiency in the machining of complex parts and in mass production.

EDM - THREAD

This process uses direct current discharges to generate a gap between the wire and the workpiece, allowing for the creation of complex geometries, both linear and conical. Its high precision makes it a preferred choice for die manufacturing.

EDM - PENETRATION

The electrode is attached to the machine head, which is connected to the positive pole, while the workpiece is connected to the negative pole. The workpiece is immersed in a dielectric fluid, and thousands of DC pulses are generated per second, causing electrical discharges that produce sparks. This phenomenon results in material removal, facilitating EDM machining with high precision and shape control.

EDM - PENETRATION

The electrode is attached to the machine head, which is connected to the positive pole, while the workpiece is connected to the negative pole. The workpiece is immersed in a dielectric fluid, and thousands of DC pulses are generated per second, causing electrical discharges that produce sparks. This phenomenon results in material removal, facilitating EDM machining with high precision and shape control.

FLAT GRINDING

In this process, the wheel rotates on a horizontal spindle and operates edge-on on the workpiece, moving in a circular and pendulum motion. It is used for high-precision work in a variety of applications, such as simple flat surfaces, flared or inclined surfaces, grooves, recessed surfaces, and complex profiles.

CYLINDRICAL GRINDING

The grinding process uses an abrasive tool composed of quartz, silicon carbide, carborundum, or corundum grains, along with a binder. This process is generally applied in the final manufacturing stage, after turning or milling, to improve the dimensional tolerance and surface finish of the product. Cylindrical grinding is performed on the external or internal surface of a part, using centers or jaws, respectively.

CYLINDRICAL GRINDING

The grinding process uses an abrasive tool composed of quartz, silicon carbide, carborundum, or corundum grains, along with a binder. This process is generally applied in the final manufacturing stage, after turning or milling, to improve the dimensional tolerance and surface finish of the product. Cylindrical grinding is performed on the external or internal surface of a part, using centers or jaws, respectively.

TIG, MIG, ARGON, HIGH FREQUENCY WELDING (BRONZE, ALUMINUM)

It is a process by which two metallic materials are added, fused, or welded together. We have specialized equipment that allows us to process a wide variety of materials, adapting to the specifications of the application or particular need.

SANITARY POLISH

Polishing is a process that refines the metal surface of objects, removing marks, scuffs, scratches, and welding residue. In our pieces, appearance is a crucial factor, not only for aesthetic reasons but also because it contributes to extending the lifespan of the components.

SANITARY POLISH

Polishing is a process that refines the metal surface of objects, removing marks, scuffs, scratches, and welding residue. In our pieces, appearance is a crucial factor, not only for aesthetic reasons but also because it contributes to extending the lifespan of the components.

3D Scan

3D scanning is an inspection technique that utilizes the capture of massive point clouds using 3D metrology equipment or terrestrial scanners. Capture techniques can vary considerably depending on specific objectives and application sectors, including reverse engineering, dimensional quality inspection, plant surveying, and complex facility modeling.

3D RESIN PRINTING

It's an advanced technology that allows ideas to materialize through a pool of liquid resin, which, combined with a digital lighting system, solidifies the piece from the bottom up. This material, whether rigid or flexible, provides delicate finishes in 3D-printed parts. The parts produced by this 3D printer boast high precision, ensuring an excellent design finish.

3D RESIN PRINTING

It's an advanced technology that allows ideas to materialize through a pool of liquid resin, which, combined with a digital lighting system, solidifies the piece from the bottom up. This material, whether rigid or flexible, provides delicate finishes in 3D-printed parts. The parts produced by this 3D printer boast high precision, ensuring an excellent design finish.

PLASTIC INJECTION

Our plastic injection process molds parts using a mold into which a polymer pellet is injected under pressure. We employ high-tech auxiliary equipment that allows us to process everything from standard materials to highly engineered plastics, ensuring versatility and quality in every production run.

Founded in 2002